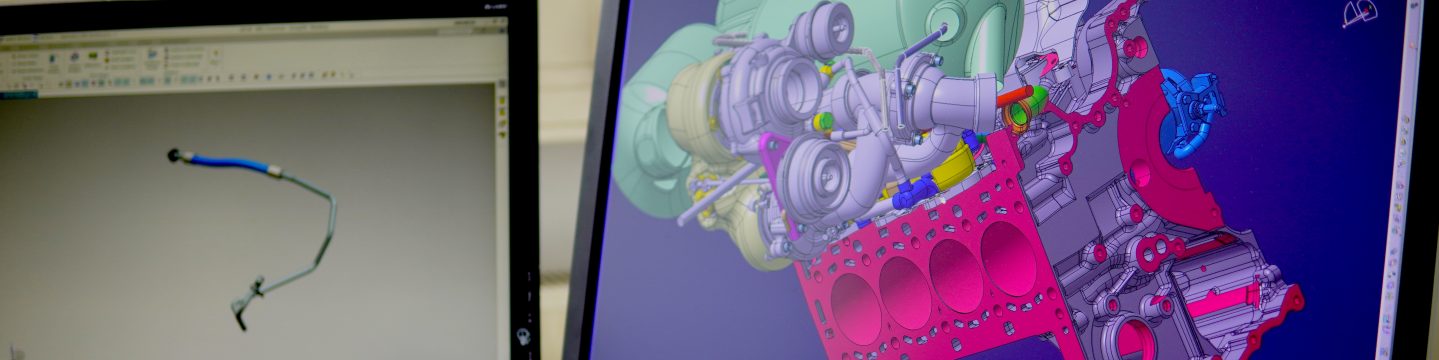

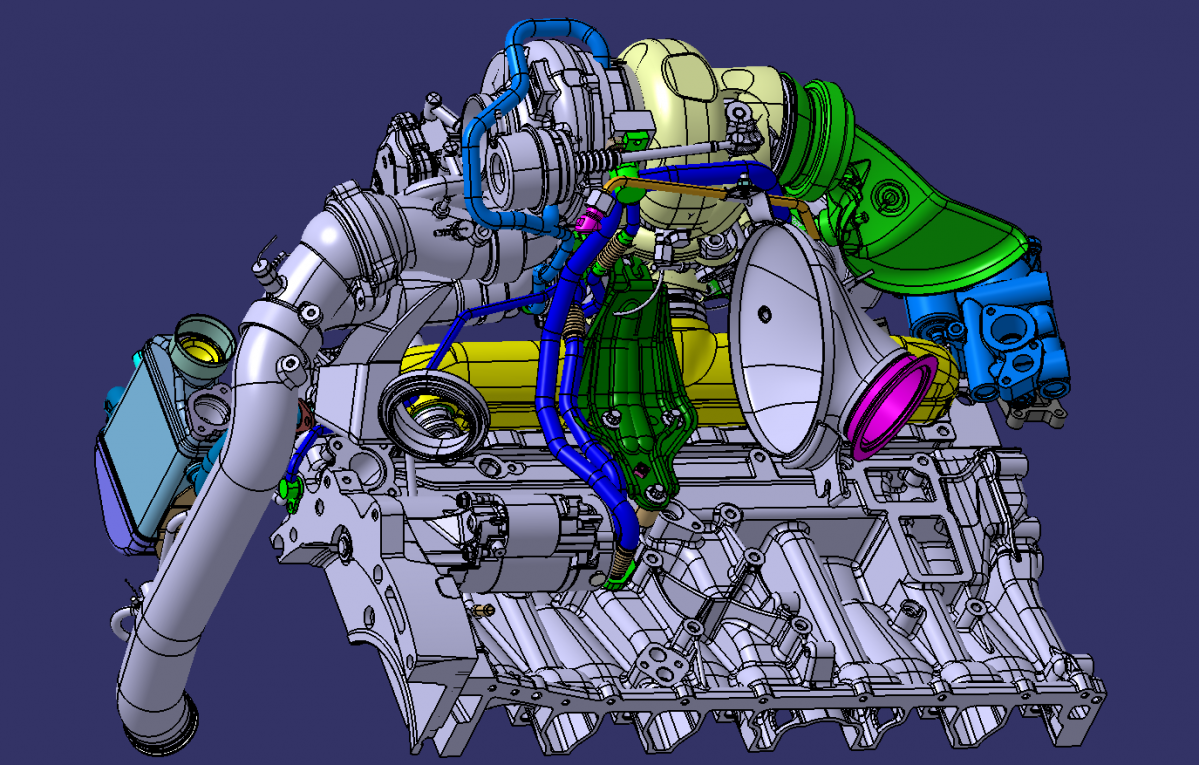

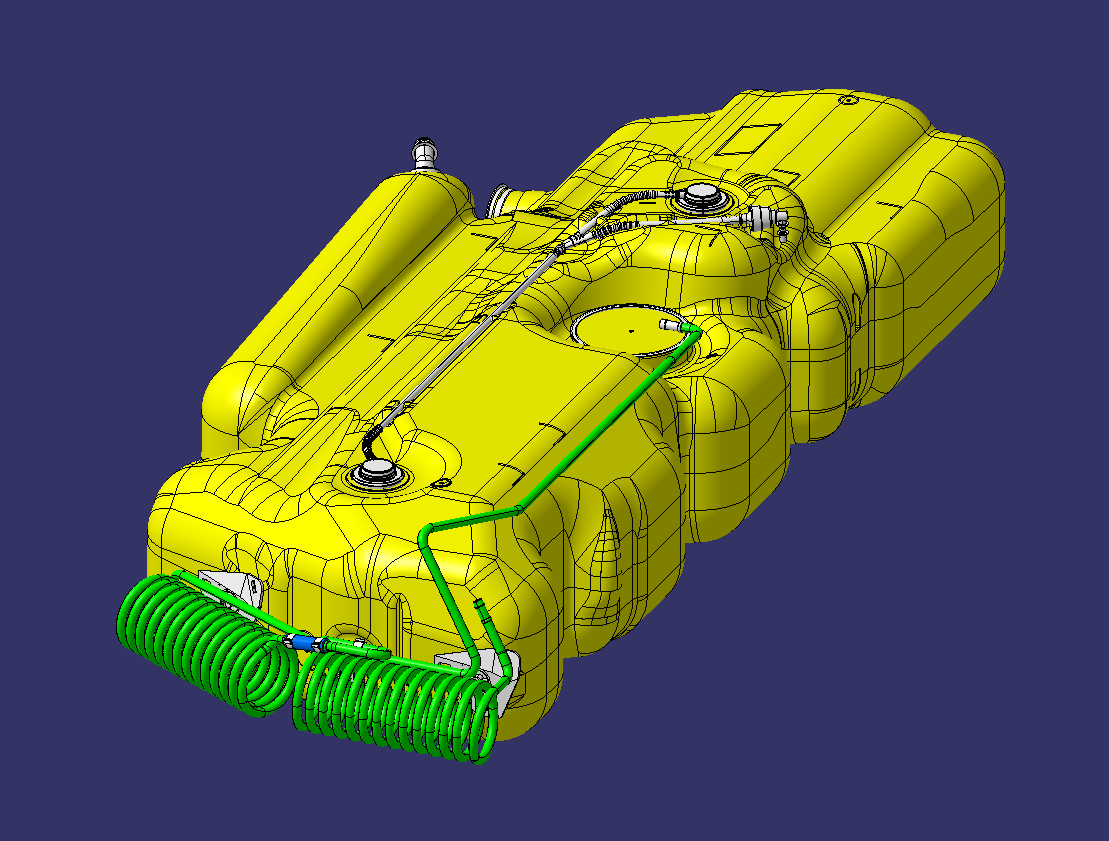

Quality through state-of-the-art laboratory and measurement technology

In order to guarantee the quality of media-carrying components on the one hand and to prove it on the other hand, a high-quality standard is at the centre of our R&D in addition to individual customer requirements. We meet this demand through our test laboratory, which is directly affiliated to our R&D. Equipped with a wide range of test systems and associated measurement technology, our test laboratory is designed to perform extensive development and validation tests on a customer-specific basis.

Among the most important test equipment in our laboratory is the..

- Alternating temperature pulse test bench

- Cooling water pulse test bench

- High pressure pulse test bench

- Aging test facility

- Cold-heat cabinet

- Bursting pressure test stand

- Tensile testing machine

- Expansion hose impulse test stand

- Acoustic test stand

With the help of these systems, our highly qualified team of experts is capable to meet the most diverse customer requirements and ensure the highest quality standards. The portfolio of testing equipment is completed by digital measuring microscopes, profile measuring equipment, digital profile testing equipment as well as surface equipment.

A little insight behind the scenes

Bursting pressure testing

To prove the quality of media-carrying lines, pipes and hose lines are pressurized until they finally burst. In our R&D, a pressure range of 30 - 2,500 bar can be realized during this testing process. Following the test, the process is precisely documented with the aim of optimally designing the media-carrying lines for specific applications.

Alternating temperature pulse test bench

A further proof of quality is provided by the alternating temperature impulse test rig. This test method is used specifically for transmission oil cooler hose lines. The transmission oil cooler hose line is subjected to both a static and a dynamic pressure test under alternating temperatures. In both types of procedure, the components are subjected to a pressure range of up to 50 bar. The temperature in the test chamber varies between -40°C and +170°C.

Expansion hose impulse test rig

Just like the alternating temperature impulse test rig, the expansion hose impulse test rig is suitable for static and dynamic pressure testing at alternating temperatures. The difference, however, lies in the component being tested. Thus, in dynamic pressure testing, expansion hose assemblies can be tested in a pressure range of up to 180 bar at changing temperatures. Static pressure testing takes place in a pressure range up to 250 bar.

Other common tests performed in our laboratory are the service life test and the residual dirt analysis. It is not uncommon for small particle residues to be found in the component. In this case, the residual dirt analysis can provide information about the particle size as well as the properties (metallic / non-metallic) of the particle.