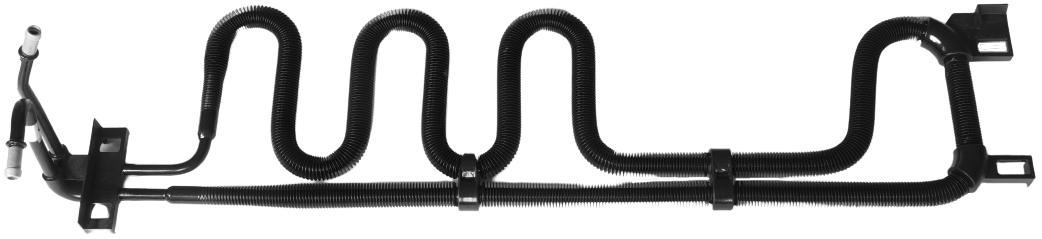

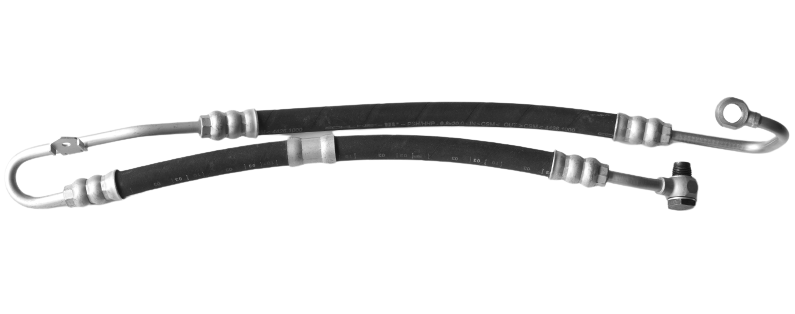

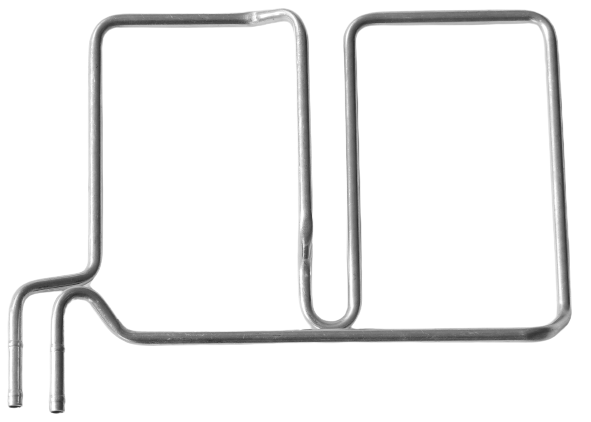

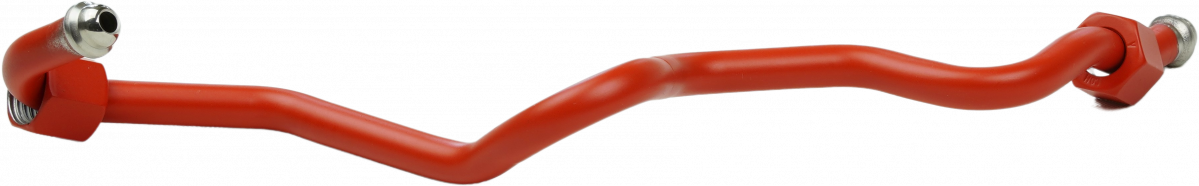

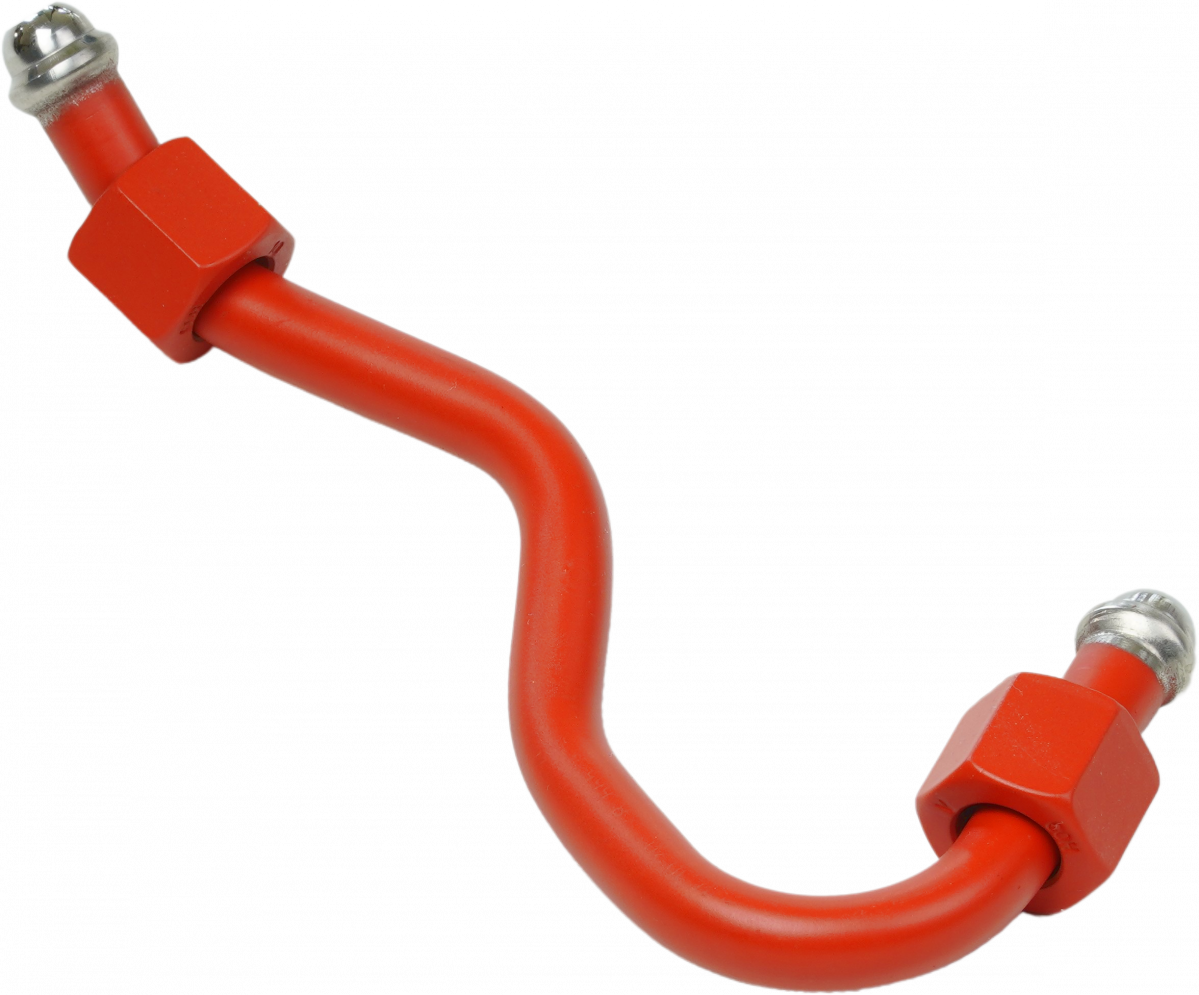

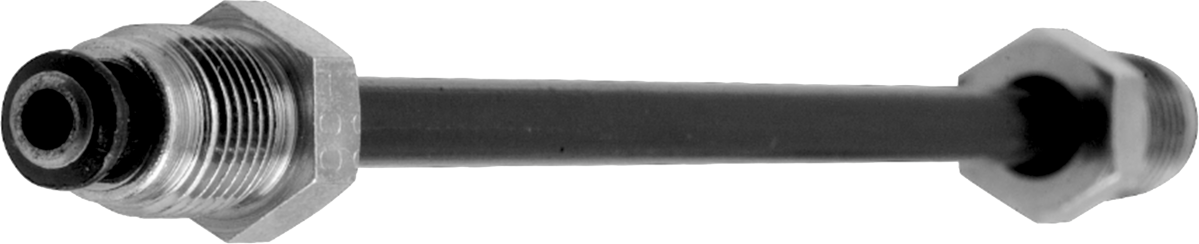

Customized products

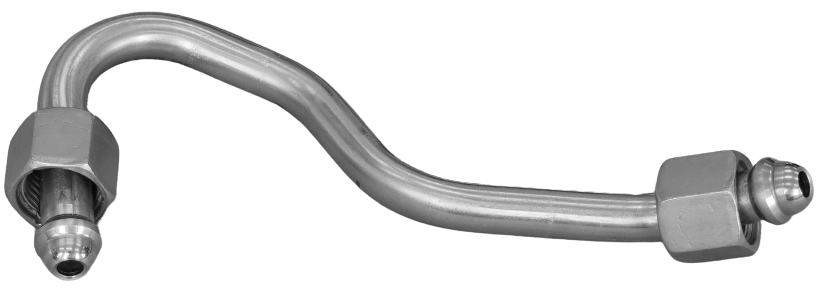

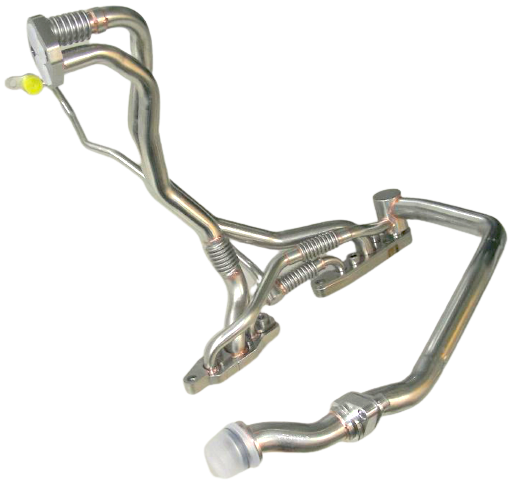

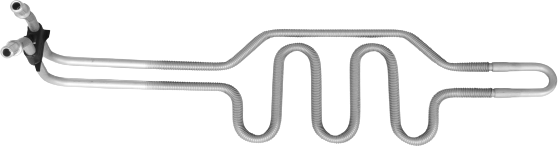

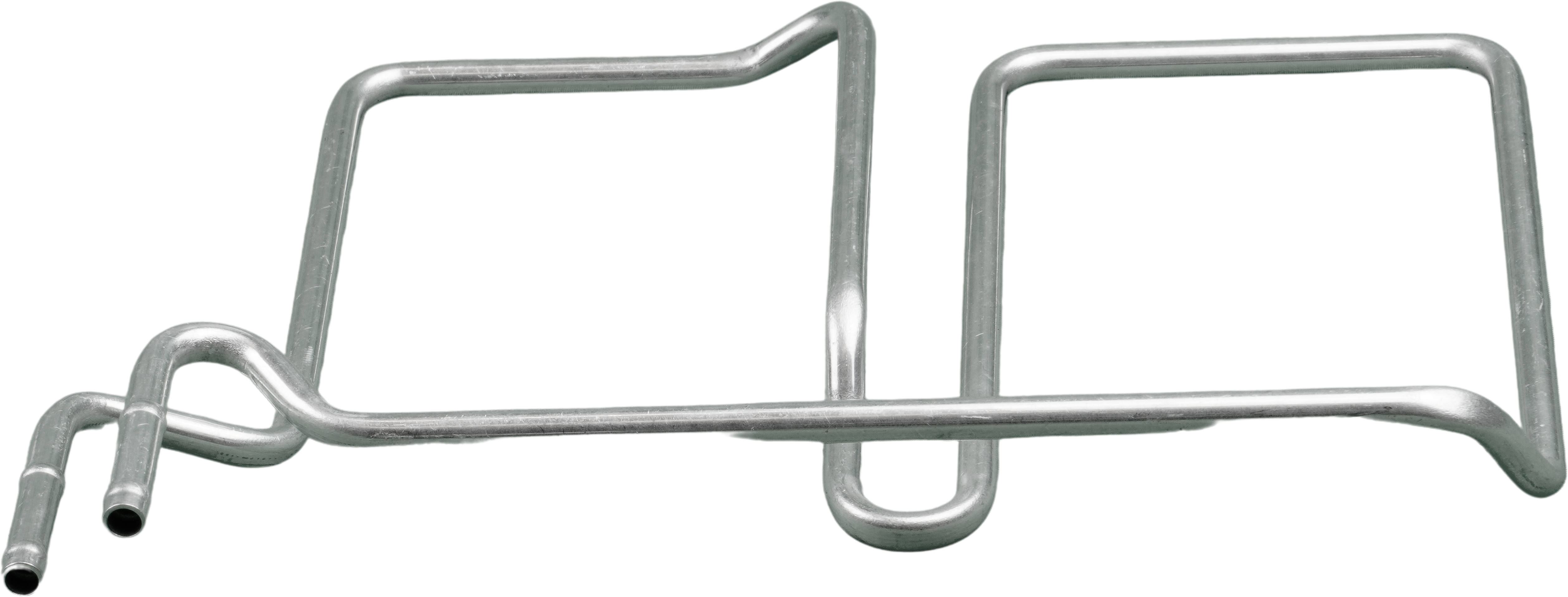

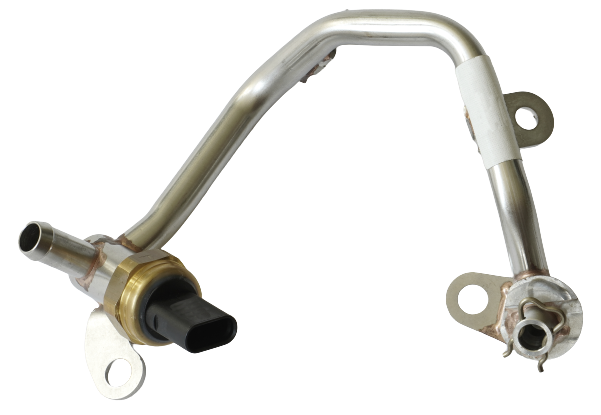

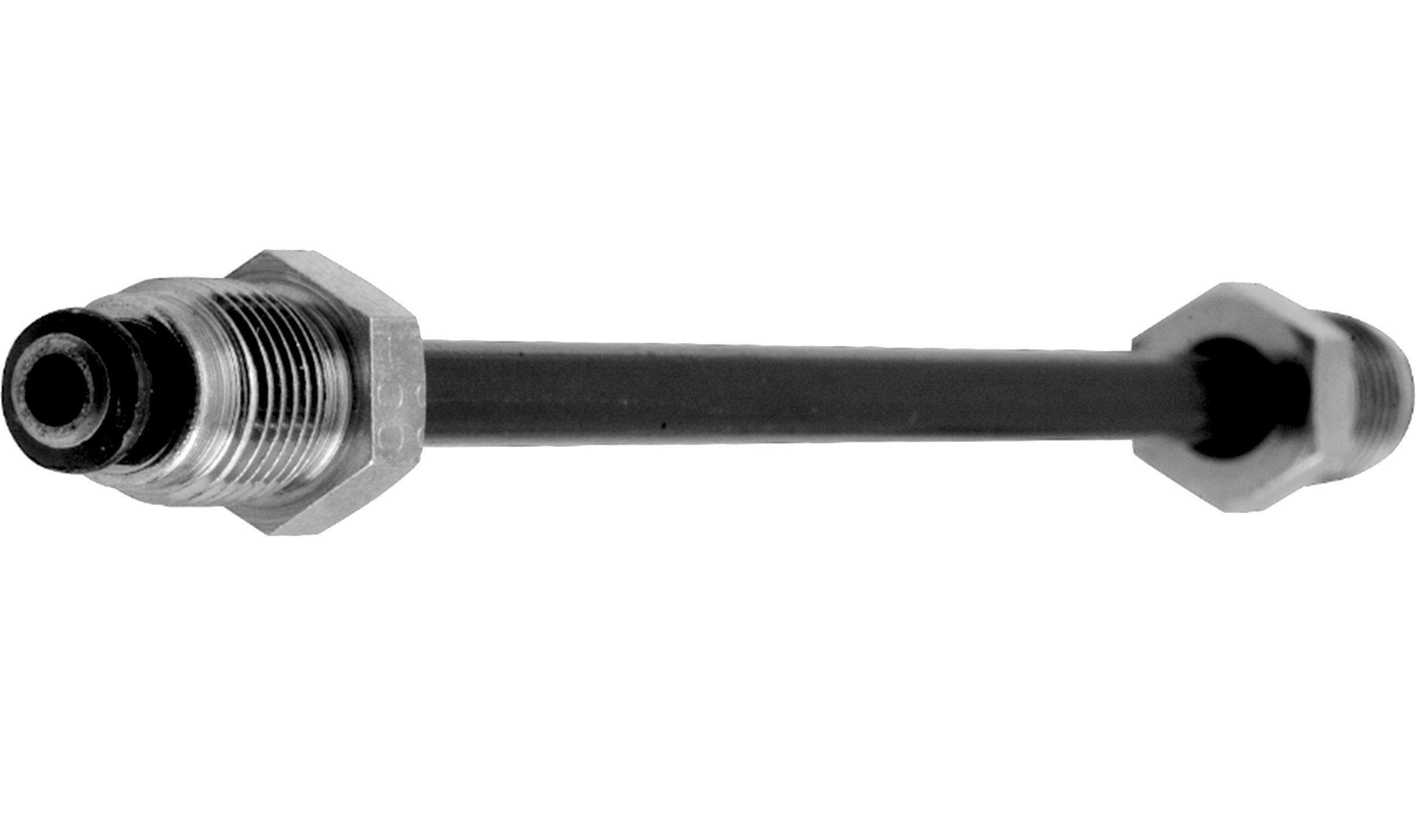

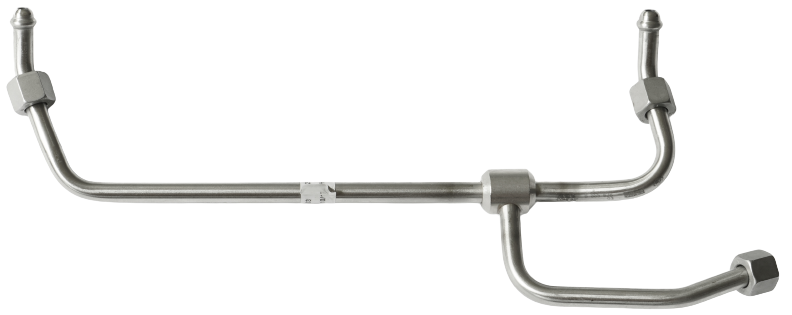

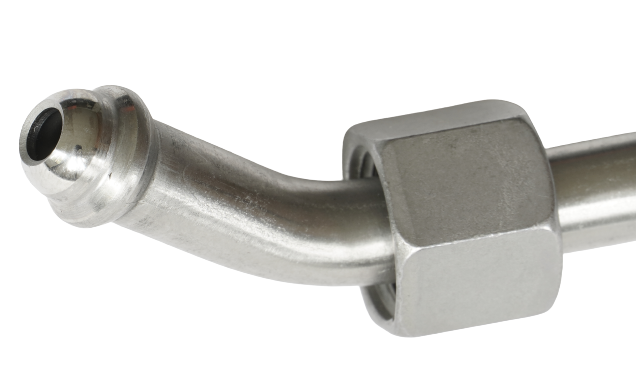

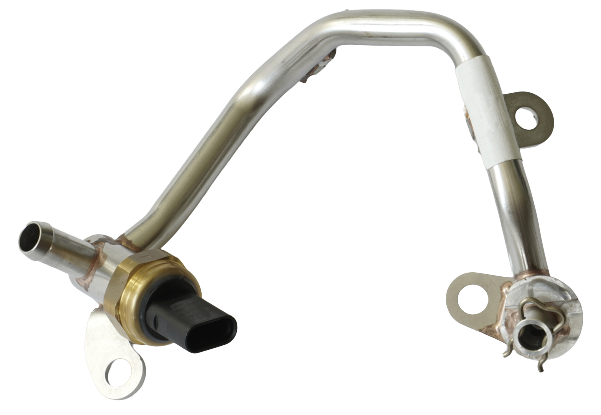

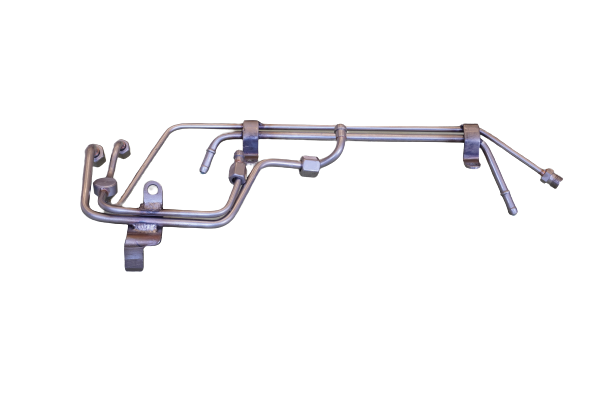

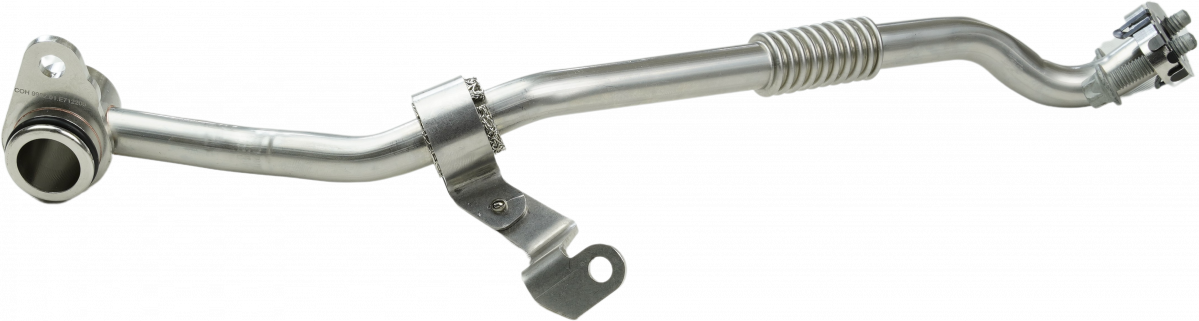

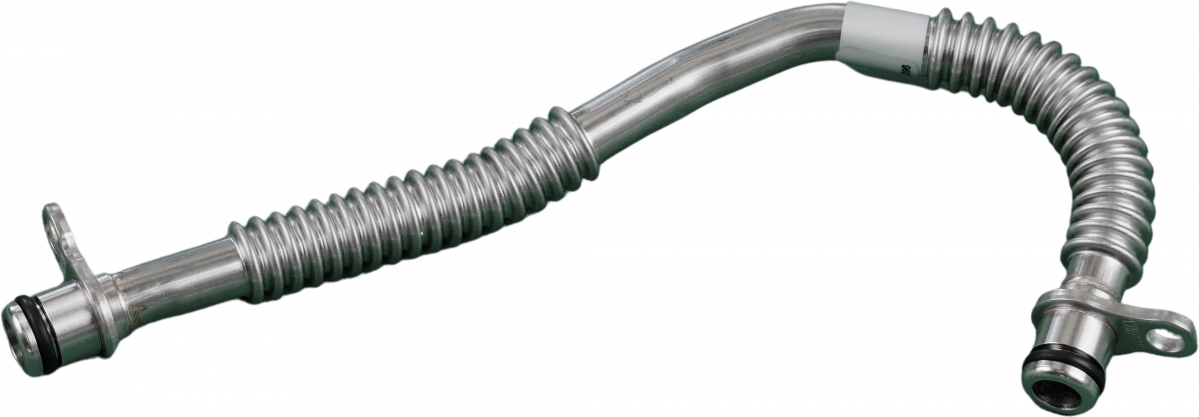

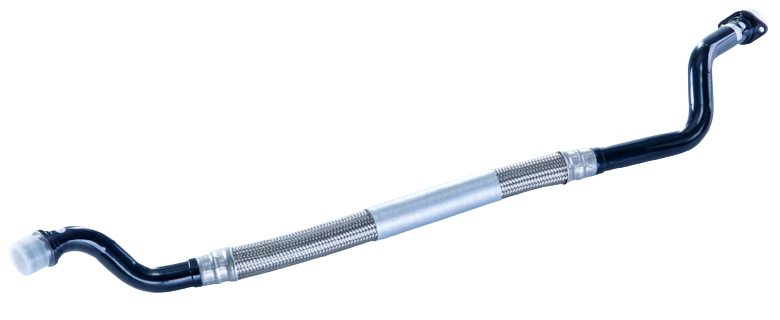

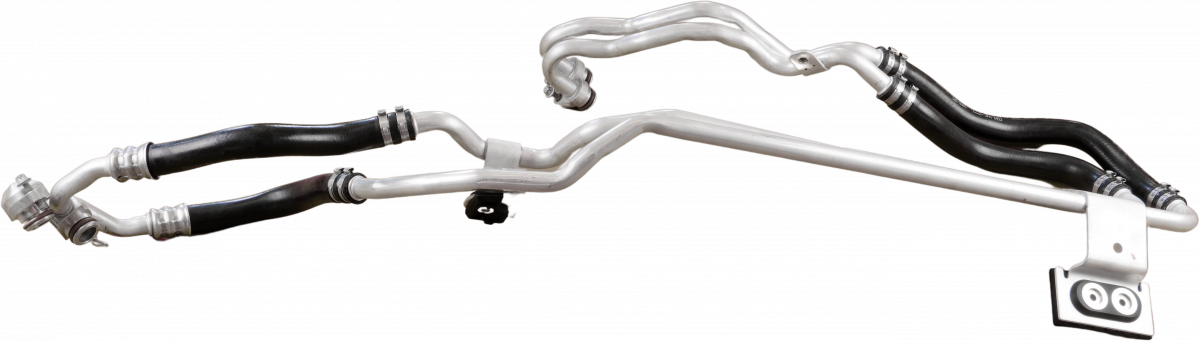

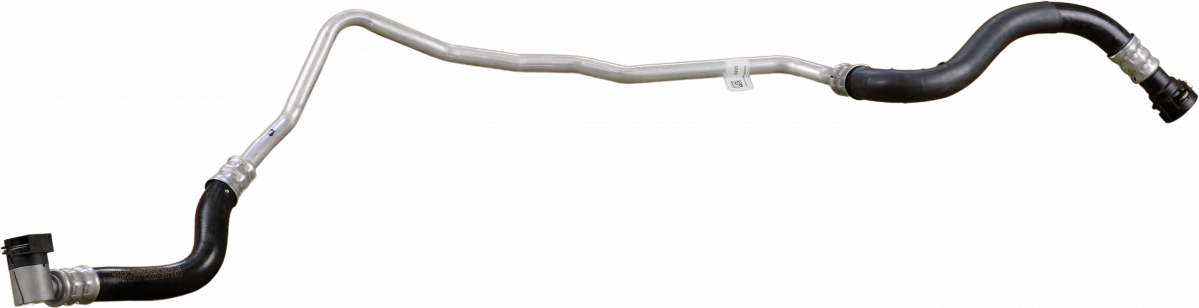

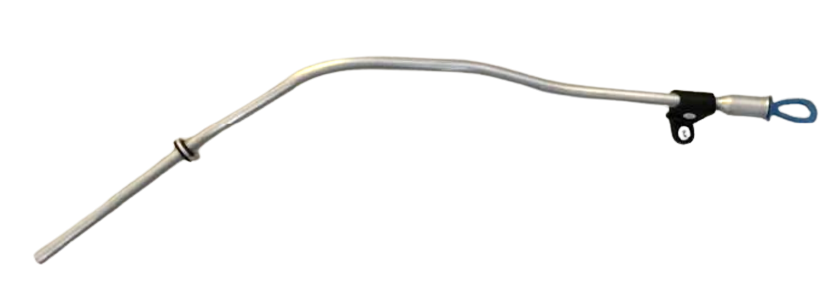

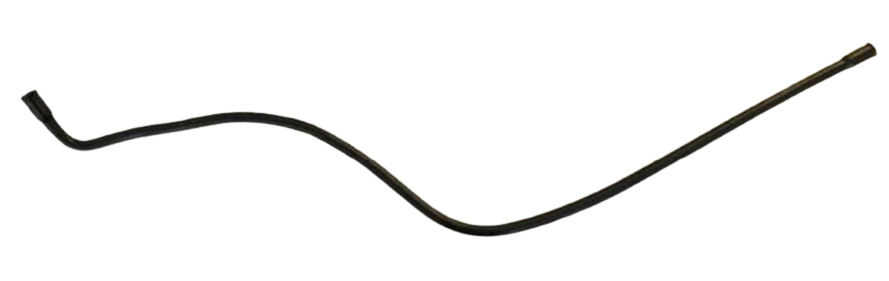

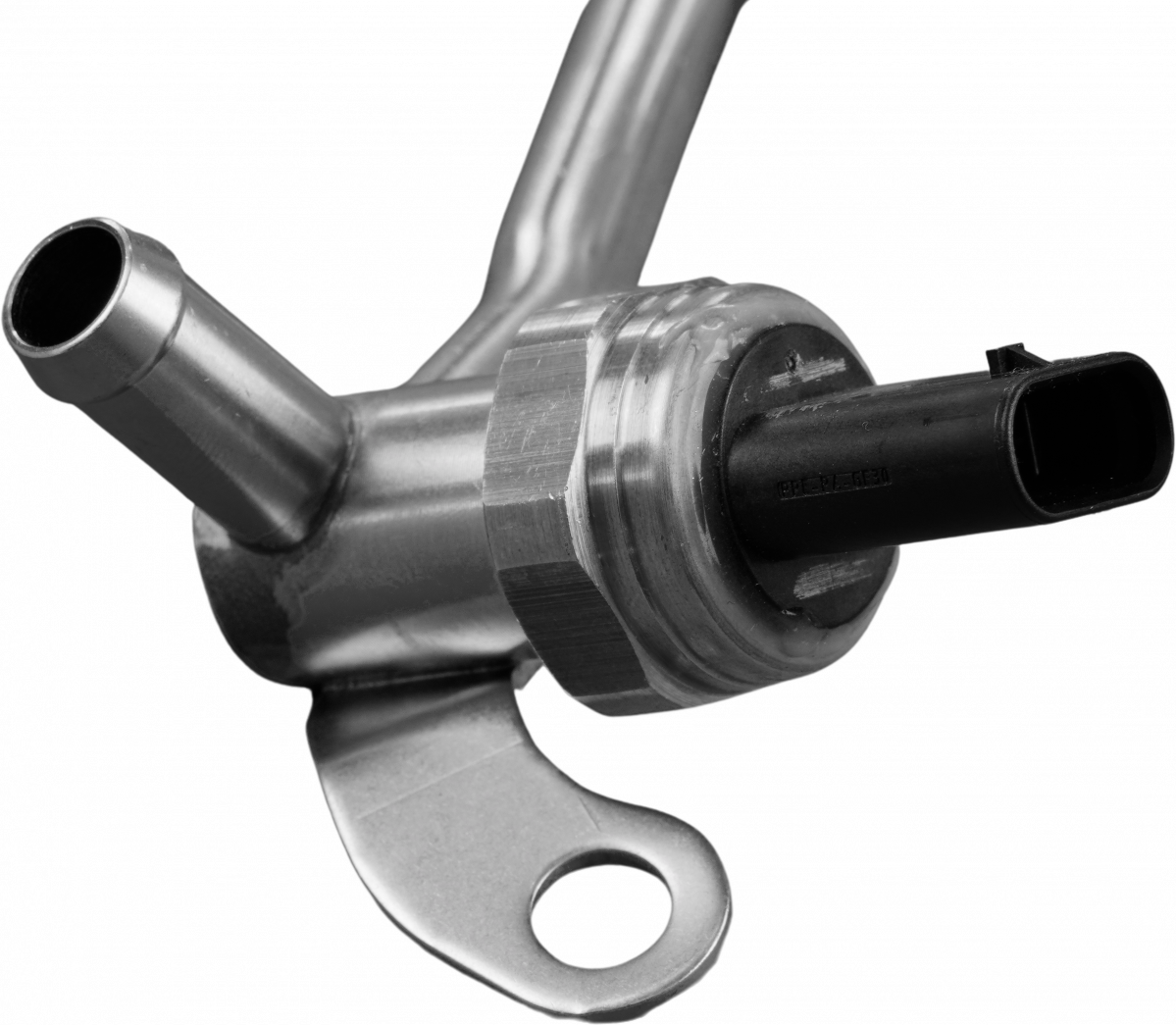

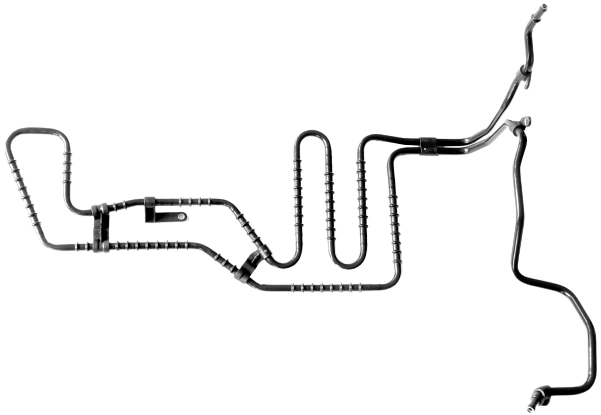

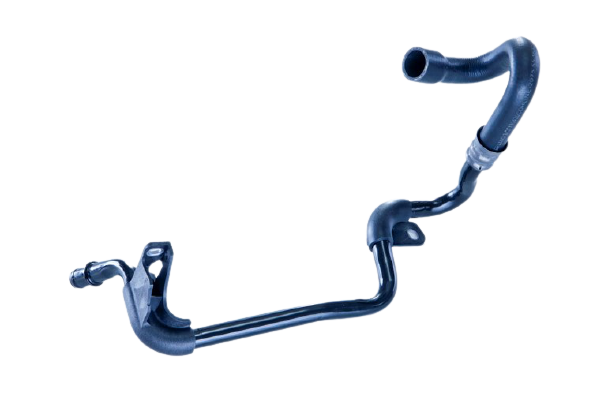

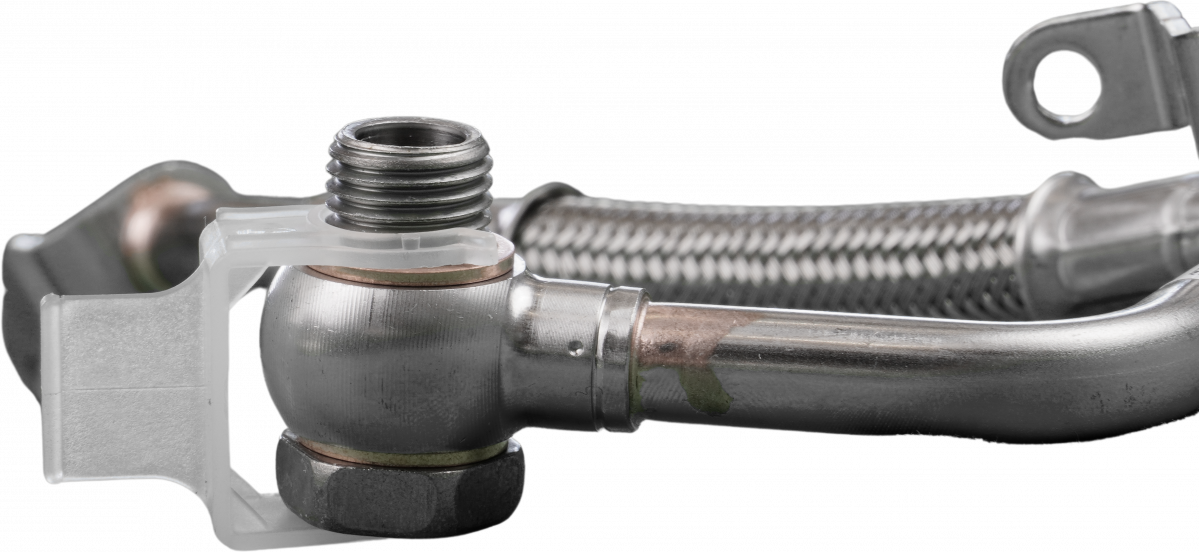

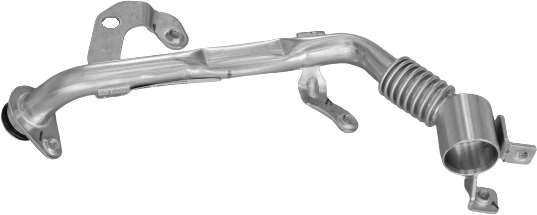

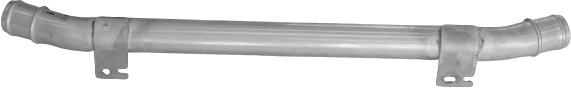

COHLINE has represented expertise and innovation since 1932. We manufacture pipe and hose line systems for various applications including oil supply, turbochargers, fuel, cooling and hydraulics. Explore our tailored solutions to meet your specific requirements.

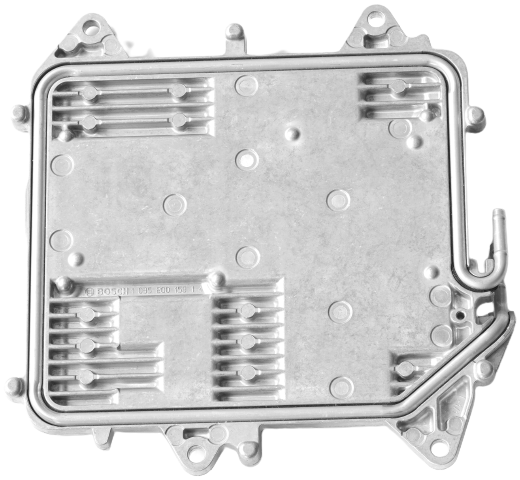

Our products adhere to the highest quality standards of renowned companies in the international automotive, commercial vehicle, construction, agricultural machinery and engine industries. Our primary focus in every development project is on the individual requirements of our customers. Regardless of yout needs, we are able to develop and provide sophisticated customer solutions utilizing cutting-edge production technology. At COHLINE, we continually strive to devise well-conceived, practical and strictly customer-oriented system solutions. Our highly qualified research and development team actively contributes to setting standards and specifications while consistently experimenting with new, innovative manufacturing processes.

Our proficiency in working with metals such as steel, stainless steel, aluminum, brass and copper, plastics such as polyamides and PTFE and elastomers such as NBR, CR, EPDM, CSM, FPM, AEM and ECO enables us to combine these materials and achieve the best possible results. Our focus is on function, quality and maximum precision - combined with an optimum price-performance ratio.